- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2025-07-11

- Zhyq

- 54

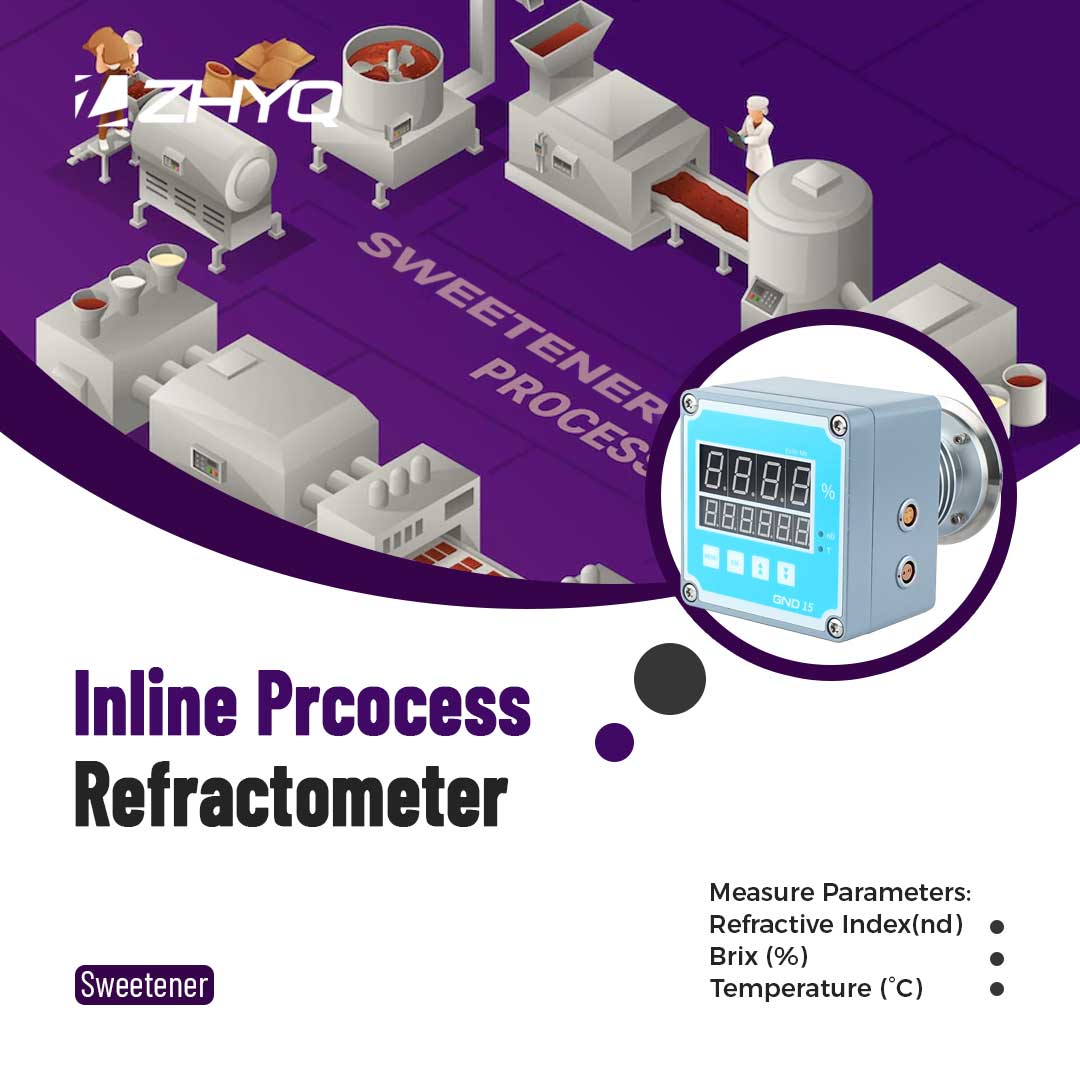

The “Super Housekeeper” In the Soy Milk Production Process – ZHYQ’s Inline Refractometer!

In the flavored beverage industry, especially in soy milk production, the quality of raw materials, production stability and product quality are the core issues that companies are most concerned about. Traditional methods are often difficult to control accurately, resulting in unstable product taste, low production efficiency and uneven quality. Are you still worried about these problems? Don’t worry, ZHYQ’s inline refractometer is here to save your soy milk production!

The “three major problems” in soy milk production:

1) Inaccurate control of raw materials

The main raw material of soy milk is soybeans, and its quality directly affects the taste and nutritional content of the final product. During the procurement and storage process, the moisture content, protein content, and sugar content of soybeans are difficult to measure quickly and accurately, resulting in unstable raw material quality. This is like buying vegetables, not knowing the quality of the vegetables, and relying on “luck”. In addition, sugars and other ingredients need to be added in the production of soy milk, and accurate control of their concentration is also crucial. If too much sugar is added, soy milk will become a “sweet trap”; if too little sugar is added, it will become bland!

2) Low production efficiency

During the soy milk production process, the concentration control of each link requires frequent sampling and laboratory testing, which is time-consuming and labor-intensive, resulting in low production efficiency. Traditional methods are difficult to monitor the concentration changes in the production process in real time, and are prone to deviations, which in turn affect product quality and production efficiency. This is like driving without navigation and can only rely on “blind driving”, which is not only inefficient but also prone to errors.

3) Inaccurate quality testing

The quality testing of soy milk usually relies on traditional chemical analysis methods, which are time-consuming, complicated to operate, and easily interfered by human factors. In addition, traditional methods are difficult to quickly detect the concentration of sugar, protein and other components in soy milk, resulting in insufficient accuracy and timeliness of quality testing.

Raw material monitoring

–Soybean testing: Use an inline refractometer to measure the refractive sugar content (Brix value) of soybean extract to indirectly evaluate its sugar and protein content. This method can complete the test in a short time to ensure that the purchased raw materials meet the quality standards. This is like having a “fire eye” that can see through the “inner quality” of soybeans at a glance.

–Additive monitoring: For added ingredients such as sugars, the inline refractometer can quickly measure their concentration to ensure that they meet production requirements. This non-destructive testing method not only improves monitoring efficiency, but also reduces sample waste. This is like having a “precision scale” to make every addition just right.

Production process monitoring

–ZHYQ’s inline refractometer can be installed on the production line to achieve online real-time monitoring. For example, in the preparation and concentration process of soy milk, the inline refractometer can provide real-time feedback on the concentration changes of the solution and adjust the production process parameters in time.

Quality Inspection

–ZHYQ’s inline refractometer is widely used in quality inspection. It can quickly measure the soluble solid content in soy milk, including the concentration of sugar, protein and other ingredients.

–In addition, the inline refractometer can also be used to detect the stability of soy milk, and determine whether the product has stratification or precipitation by measuring the change in its refractive index. This is like having a “super physical examination instrument” that can fully detect the health of soy milk.

Core Values–The “surprise” brought by inline refractometer:

1) Improved raw material quality and reduced costs

Through the application of inline refractometers, soy milk manufacturers can quickly and accurately control the quality of raw materials, reducing production delays and defective rates caused by raw material quality issues. At the same time, accurate concentration control can also optimize the use of raw materials and reduce production costs.

2) Significantly improved production efficiency

After using inline refractometers, the production efficiency of soy milk manufacturers has been significantly improved and the production cycle has been shortened. At the same time, real-time monitoring ensures the stability of the production process and reduces the defective rate caused by concentration fluctuations.

3) Accurate and efficient quality inspection

The application of inline refractometers makes the quality inspection of soy milk more accurate and efficient. It can complete the concentration detection of multiple components in soy milk in a short time, reducing the detection time and labor costs. At the same time, high-precision test results provide a strong guarantee for product quality.

ZHYQ’s inline refractometer has demonstrated its excellent performance in the soy milk industry, from raw material control, production process monitoring to quality inspection. It not only improves production efficiency and reduces production costs, but also ensures the stability and consistency of product quality. For soy milk production companies, ZHYQ’s inline refractometer is undoubtedly an indispensable “super housekeeper”.