- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2025-06-09

- Zhyq

- 156

ZHYQ’s Inline Refractometer Allows You to Know the Concentration of Machine Tool Cutting Fluid at Your Fingertips, Saving You Time, Money and Tools!

Q:Are you still troubled by these problems?

A:The wear of machine tool tools is abnormally accelerated, and the quality of machined surface is sometimes good and sometimes bad, but you can’t find the exact reason? The concentration of cutting fluid is manually checked regularly, which is time-consuming and labor-intensive, and the results are delayed and prone to errors? If the concentration is low, the cooling and lubrication are insufficient; if the concentration is high, the concentrated liquid is wasted and prone to foaming and stinking? Sudden loss of concentration control leads to batch scrapping of workpieces or equipment shutdown, resulting in heavy losses?

Cutting fluid concentration: the “blood” management problem of machine tool processing!

Cutting fluid is known as the “blood” of machine tool processing. Its concentration directly determines the lubrication, cooling, rust prevention and chip removal performance. If the concentration is too low, it is like “anemia”, which leads to increased tool wear, rough workpiece surface and even rust; if the concentration is too high, it is like “viscous blood”, which not only wastes expensive concentrated fluid, but also may cause foam and bacterial growth, affecting the processing environment and equipment life.

The traditional manual handheld refractometer detection method has many shortcomings!

Lag: Unable to reflect concentration changes in real time, it is too late to find problems.

One-sidedness: The sampling point may not represent the overall tank liquid concentration.

Low efficiency: It consumes manpower and is difficult to cover multiple devices.

Large error: It is significantly affected by operator experience, ambient temperature, and oil pollution.

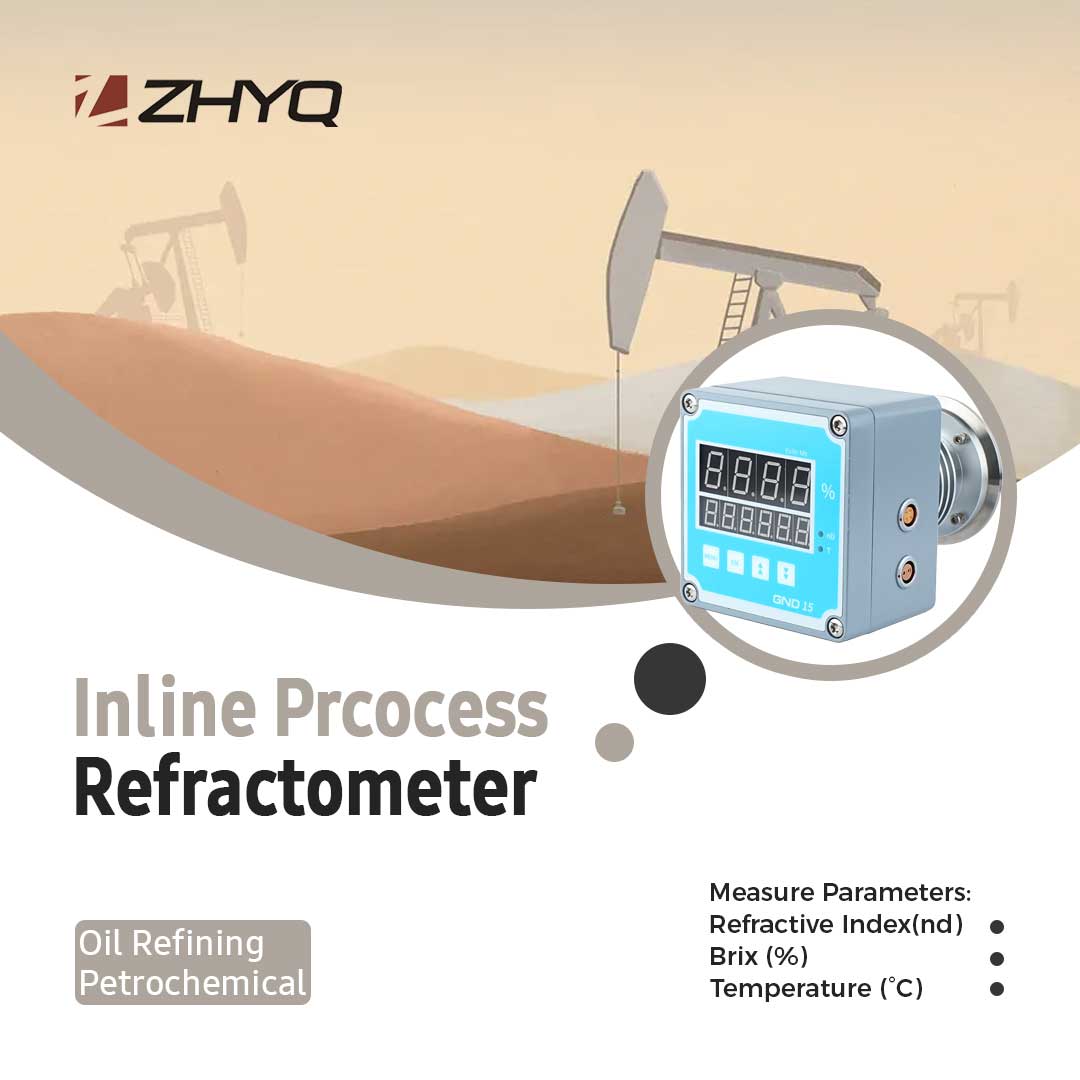

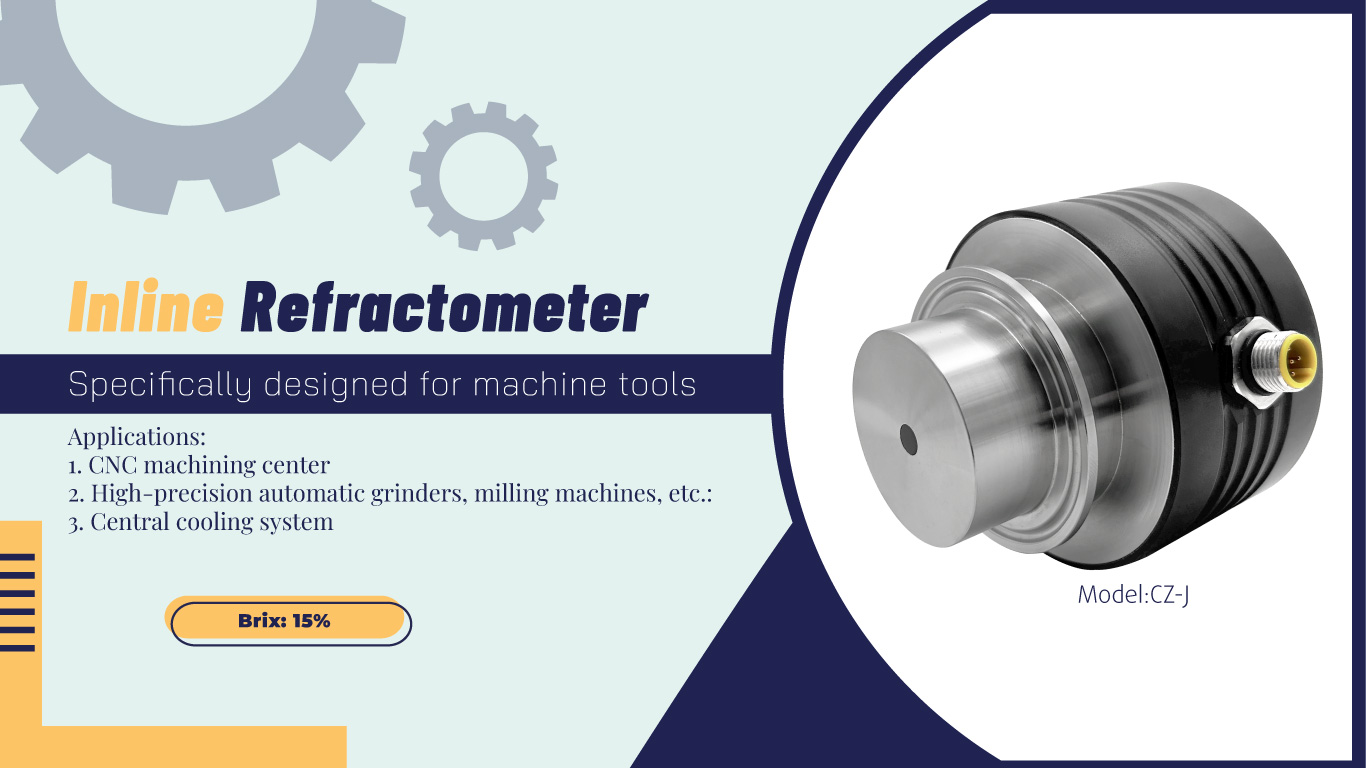

ZHYQ’s inline refractometer, the “full-time guardian” of machine tool cutting fluid concentration!

ZHYQ has been engaged in the field of industrial process measurement for many years and has launched a series of high-performance inline refractometers, which are specially designed to solve the pain points of cutting fluid concentration monitoring in the machine tool industry! It is like installing “smart eyes” and “early warning radar” for your cutting fluid tank, providing accurate and real-time concentration data 24/7.

Visible benefits, calculable returns!

1. Real-time and accurate monitoring, say goodbye to the risk of loss of control:

ZHYQ inline refractometer adopts high-precision ATR prism technology, combined with advanced temperature compensation algorithm, it can measure the concentration of cutting fluid in real time, continuously and accurately (typical accuracy ±0.3%) even in the complex environment of the workshop. The data is instantly displayed on the local transmitter or uploaded to your PLC/SCADA system, the concentration fluctuation is clear at a glance, and the risk hidden dangers can be discovered in time.

2. Stabilize machining quality and extend tool life:

Ensure that the cutting fluid concentration is always stable within the optimal range required by the process, providing constant lubrication and cooling performance. Significantly reduce abnormal tool wear, extend tool life by up to 15%-30%, and significantly reduce tool costs. Improve the surface finish and dimensional accuracy consistency of workpiece machining, and reduce scrap rate.

3.Optimize the use of cutting fluid and reduce overall costs:

Avoid excessive concentration: Reduce the waste of excessive addition of concentrated liquid. Prevent too low concentration: Avoid premature failure of the entire tank liquid due to insufficient concentration, and extend the service life of the tank liquid. Accurate refilling: The automatic refilling system can be easily integrated to achieve intelligent concentration management and save manual operation costs.

4. Intelligent alarm linkage to prevent accidents before they happen:

Freely set the upper and lower alarm values of the concentration. Once the concentration deviates from the safe range, it will immediately trigger the sound and light alarm or control related equipment (such as shutdown protection) through relay output, or link the automatic liquid replenishment system to intervene. Remote monitoring: Support Modbus and other communication protocols, data can be connected to the factory MES/IIoT platform to achieve remote centralized monitoring and management, and improve management efficiency.

Advantages of ZHYQ’s inline refractometer, designed for harsh machine tool environments:

1. Sturdy and durable, no fear of oil pollution: The measuring end of the refractometer is made of high-quality stainless steel (such as 316L) or special alloy material, with high protection level (IP67/IP68), which can withstand cutting fluid corrosion, oil splash and harsh workshop environment.

2. Intelligent anti-fouling design (key!): Chaohui provides a variety of solutions to the problems of cutting fluid oil pollution and impurity adhesion

3. Optional ultrasonic cleaning function: Regularly and automatically clean the prism surface to maintain measurement accuracy.

4. Special coating or mechanical scraper (specific model): Effectively resist oil adhesion.

5. Bypass installation recommendation: Through the circulation filtration system, the direct impact of impurities in the main tank on the probe is reduced, and the measurement is more stable and reliable.

6. Flexible installation and easy maintenance: Support direct immersion or better bypass circulation installation. The transmitter has a simple design and convenient parameter setting and calibration.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *