- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2025-06-17

- Zhyq

- 108

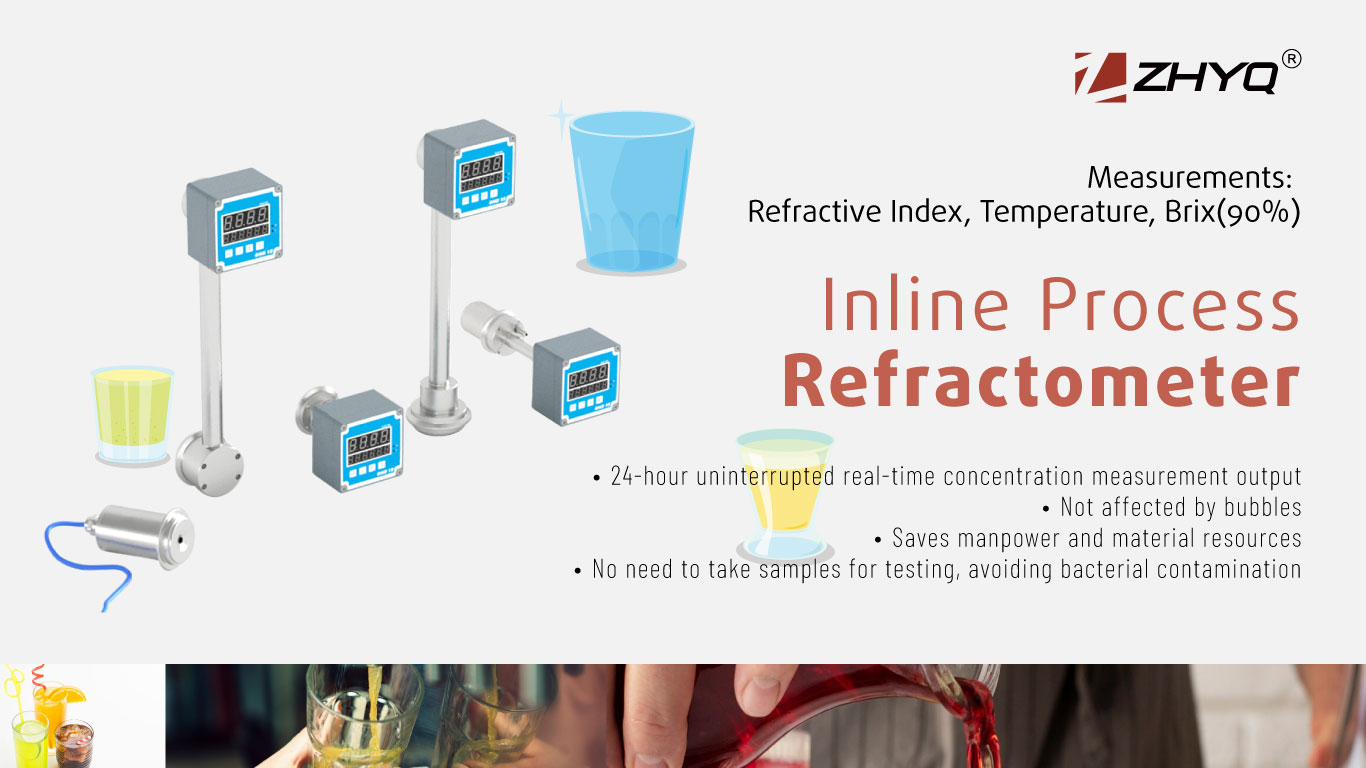

ZHYQ’s Inline Refractometer Ensures the Quality of Food and Beverages Throughout the Entire Process!

Say goodbye to manual sampling and control the medium concentration in real time! ZHYQ’s inline refractometer makes every drop of delicious food just right!

In the food and beverage industry that pursues the ultimate taste and stable quality, concentration (sugar content/Brix, solid content, etc.) is the core lifeline:

1. The thickness of jam determines the taste and spreadability;

2. The sugar content of juice and beverages is the key to flavor consistency;

3. The solid content of dairy products is related to texture and nutrition;

4. The concentration of condiments and sauces directly affects the flavor intensity and shelf life. However, the traditional offline detection method that relies on manual sampling, laboratory testing or handheld refractometers is inefficient and has too high uncertainty!

5. Serious lag: When the results come out, a whole batch of products may have deviated from the standard.

6. Questionable representativeness: Single-point sampling cannot reflect the real-time changes in concentration in the pipeline or tank.

7. Inefficiency: Time-consuming and labor-intensive, affecting the production rhythm.

8. Human error: Operation techniques and ambient temperature can easily affect the accuracy of the results.

9. Safety hazards: Frequent canning and sampling increase the risk of contamination.

How to solve the problem of concentration control and ensure that every batch meets the standards perfectly?

ZHYQ’s inline refractometer: the “invisible quality guardian” of food and beverage production

Shanghai Zhaohui Pressure Instrument Co., Ltd., relying on its profound accumulation in the field of industrial precision measurement, has launched a series of high-performance, high-hygiene inline refractometers. It is like a “smart taste bud” installed on your production line, monitoring the concentration of key process points in real time 24 hours a day, 7 days a week, without pollution, providing a solid guarantee for stable quality and efficient production!

Core values: precision, efficiency, safety, driving excellent quality of food and beverages!

Real-time and accurate monitoring, quality control throughout the process:

Zhaohui inline refractometer uses high-precision ATR prism technology and advanced algorithms to directly measure the refractive index of the solution and accurately convert it into Brix, solid content or custom concentration value (typical accuracy can reach ±0.1% Brix).

Instant feedback of concentration changes allows operators or automation systems to grasp information at the first time, ensuring that every drop and every can strictly meets the process standards and the taste and flavor are consistent!

Improve production efficiency and optimize resource utilization:

1. Completely replace time-consuming and labor-intensive manual sampling, release valuable manpower, and allow employees to focus on higher-value work.

2. Seamless integration of automation: Real-time concentration signals can be directly input into the PLC/DCS system for:Precise batching and mixing control: Ensure that the raw material ratio is accurate.

3. Determination of the end point of the evaporation/concentration process: Real-time monitoring of concentration changes, automatic stop when the target value is reached, saving energy and avoiding over-concentration.

4. Standardized control: Real-time adjustment in the mixing and dilution links to ensure constant concentration of the finished product.

5. Filling monitoring: Ensure that the concentration of the filled product meets the specifications.

6. Reduce waste: Avoid batch failures, rework or scrapping due to concentration deviation, and significantly reduce raw material costs.

Ensure food safety and compliance:

1. Hygienic design: The contact material is made of food-grade material (such as 316L stainless steel, Hastelloy), with high surface finish (Ra ≤ 0.8μm), which meets the requirements of EHEDG, 3-A and other hygiene standards, and is easy to clean by CIP/SIP, eliminating sanitary dead corners.

2. Non-contact measurement: The measuring port is directly immersed in or contacts the material through a sanitary flow cell, without opening the can for sampling, greatly reducing the risk of microbial contamination and meeting strict GMP and HACCP requirements.

3. Data traceability: Concentration data is recorded and stored in real time, providing complete and reliable electronic records for production process traceability, quality analysis and compliance audits.

4. Intelligent temperature compensation: Built-in high-precision temperature sensor , automatically compensates for the effect of temperature on refractive index, and ensures accurate readings under various working conditions.

5. Anti-pollution design: For problems such as bubbles, particles, fibers, high viscosity, crystallization tendency, etc. that may exist in food materials.

6. Optional ultrasonic self-cleaning function automatically removes attachments on the prism surface.

7. Optimized design of sanitary flow cell provides stable flow field and reduces interference from bubbles and particles.

Special surface treatment or coating (specific models) enhances anti-fouling ability.

8. Rugged and durable: High protection grade (IP67), suitable for humid and complex production environments.

Widely used scenarios:

1. Fruit juice, fruit and vegetable juice: Raw material acceptance, concentration process control, final product sugar content/Brix detection, and blending standardization.

2. Dairy products: Solids/total solids content monitoring in milk, yogurt, condensed milk, and milk powder production, and concentration endpoint control.

3. Soft drinks, alcoholic beverages: Syrup preparation, sugar content control, and original juice content monitoring.

4. Jam, jelly, and sauce: Cooking/concentration process control, and final product consistency and solid content guarantee.

5. Sugar and starch industry: Real-time monitoring of sugar solution concentration and starch slurry concentration.

6. Condiments (soy sauce, vinegar, etc.): Fermentation process monitoring and final product concentration consistency control.

Zhaohui’s advantages, customized services:

1. Rich product lines: Provide online refractometers with a variety of ranges, precisions, materials and installation methods (immersion type, sanitary flow cell type) to meet different process requirements.

2. Sanitary certification: Key models provide material certification and design documents that comply with food industry specifications.

3. Professional support: Shanghai Zhaohui has experienced food industry application engineers, providing full-process services from selection consultation, installation guidance to commissioning and maintenance.

4. Localized response: Fast and efficient pre-sales and after-sales support to ensure the stable operation of your production line.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *